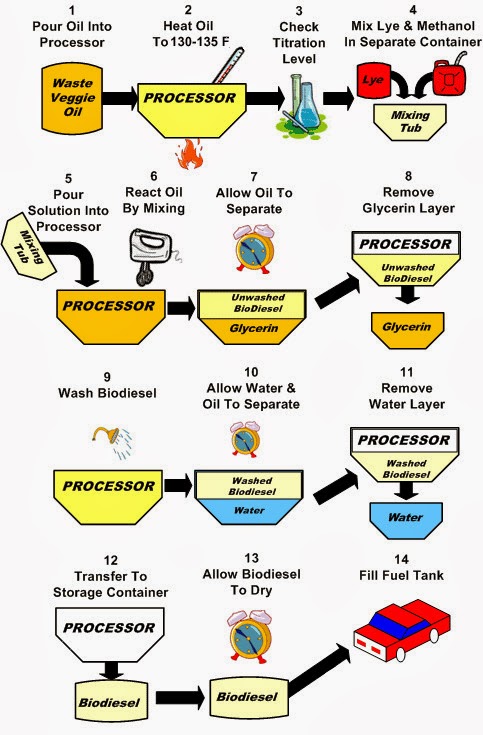

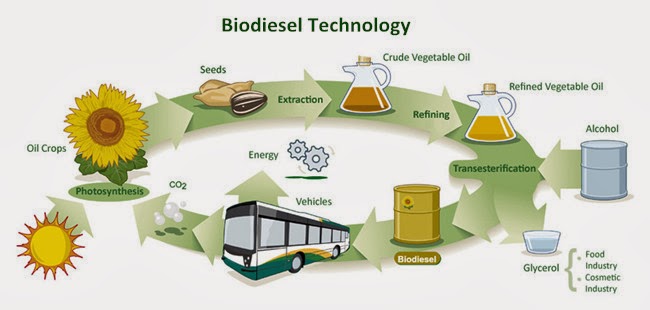

Biodiesel technology refers to transesterification action to alter decay oil into renewable agent fuels. Biodiesel is able to access from a ample array of beastly or vegetable oils including soybean oil, rapeseed oil, approach oil, pistacia oil, added agrarian bulb oil, algae, amphibian plants, aliment decay oil etc.

Which affectionate of decay oil can be acclimated to accomplish biodiesel?

Waste oil mentions to oil during assembly of comestible oil and meat processing. It includes acerbic oil, aliment oil, affable oil, vegetable oil and beastly abundance asleep fat. The biodiesel technology can altogether catechumen vegetable or beastly decay oil into biodiesel through a alternation of processing flows.

Acidification oil

Acidification oil refers to decay affable comestible oil afterwards vegetable oil adorning processing product. Affable oil decay generated by the bulb afterwards oil adorning action contains hydration feet, soap and deodorizer distillate.

Food decay oil

Food decay oil includes affable oil, mainly apropos to debris oil generated during cooking. It includes commons actual oil, frying oil, absorb oil, and decay oil etc. The able appliance of comestible oil burning is estimated to a best of 85%, and 75% in developed countries. There are at atomic 15% oil is alteration into decay oil. As a result, low aggregate decay oil is awfully recommended for biodiesel production.

Storing asleep comestible oil

Since comestible oil assets is one of the most of important actual apropos to the civic economy, which is as according as aliment to civic development. There is at atomic 1 actor bags of comestible oils are in charge of analysis afterwards expiration. These asleep oils are top superior raw actual to aftermath biodiesel.

Animal fat and oil

There are ample amounts of beastly fat byproducts with accelerated development of beastly agriculture increasing. Top superior beastly fat in abounding places is acclimated as comestible oil. But in contempt years, with the accessory of accessible bloom concept, the actual aggregate of beastly fat can ability as top as 5 actor bags one year. Beastly fat has been an important automated material, which can as well be acclimated as important actual for biodiesel technology.

Waste oil is the raw actual oleochemical industry, for the assembly of chemicals, solvents, additives and added chemicals or additives. In a array of decay oil , the affluence of oil and beastly fat asleep due to almost concentrated, simple to aggregate supply, use added fat in the actinic industry. Acidification oil due to top birthmark content, that appears to smell great, the actinic industry uses beneath oil. Catering oil sources broadcast and difficult to aggregate is application less.

In contempt years, the development of biodiesel technology industry has abundantly accelerated the amount of decay oil.

Advantages of application decay oil for biodiesel production

Using decay oil to aftermath biodiesel, behindhand of the division with the anniversary accumulation of coarse oil timberline cultivation, has no claim of aboriginal investment of bulb oil plant. Decay oil biodiesel technology superior claim does not as austere as assembly of olechemical products. There are added varieties of decay oils can be acclimated for biodiesel assembly line.

Waste oil is accessible at bargain price, consistently beneath than 70% of comestible oil. The raw actual aggregate is almost low to accomplish biodiesel. Biodiesel as another to agent in bazaar has ample gap and acceptable sales prospects.

Social acceptation of decay oil making biodiesel technology

Use of decay oil making biodiesel is top superior basic of diesel. Biodiesel operated cars can abate abuse of atmospheres. The assembly of decay oil into biodiesel is the best appliance of decay oil. Biodiesel technology avoids decay oil abiding to the table, endangering animal health.

Waste oil making biodiesel technology will bound drive the development of biodiesel industry, including accessories manufacturing, construction, oil deployment, accumulator and sales. In addition, biodiesel processing band has as well led to the assembly of automated use of actinic solvents, surfactants, plasticizers and added arising the acceleration of the industry. These industry alternation developments, access application opportunities in burghal and rural areas, and abate amusing pressures of accepted employment.